In a world increasingly aware of the environmental consequences of plastic waste, innovators are turning to nature for sustainable solutions. One of the most promising alternatives to traditional packaging materials is mycelium, the root structure of fungi. Mycelium-based packaging is gaining traction as an eco-friendly substitute for styrofoam, offering a biodegradable, renewable, and safe option for a wide range of applications.

Mycelium is the vegetative part of a fungus, consisting of a network of fine, white filaments known as hyphae. It serves as the main body of the fungus, playing a crucial role in nutrient absorption and growth. Mycelium can be found in soil, decaying organic matter, and trees, where it forms symbiotic relationships with various organisms.

Mycelium is an essential component of ecosystems, contributing to several key processes:

Decomposition: Mycelium breaks down dead plant and animal material, recycling nutrients back into the soil. This process promotes soil health and is vital for maintaining ecological balance.

Nutrient Exchange: Mycelium forms relationships with plant roots, known as mycorrhizal associations. These partnerships enhance nutrient uptake for plants, particularly phosphorus, while providing fungi with sugars produced by photosynthesis.

Soil Structure: The network of mycelia helps create soil structure, improving water retention and aeration. Healthy mycelium networks contribute to fertile soils and promote healthy ecosystems.

Carbon Sequestration: Mycelium plays a role in carbon cycling by capturing carbon from decomposing organic matter. This process helps mitigate atmospheric carbon levels, contributing to climate change mitigation.

Styrofoam, a trademarked brand of expanded polystyrene (EPS), is widely used for packaging, insulation, and disposable food containers. While it offers advantages such as lightweight and insulation properties, its environmental impact is significant.

Non-Biodegradability: Styrofoam is notoriously difficult to break down, taking hundreds of years to decompose in landfills. As it breaks down, it can release toxic chemicals into the environment.

Plastic Pollution: Styrofoam contributes to the plastic pollution crisis. Once discarded, it can be carried by wind and water into oceans and waterways, posing threats to wildlife and ecosystems.

Resource-Intensive Production: The production of Styrofoam requires petroleum, a non-renewable resource. The extraction and processing of fossil fuels contribute to greenhouse gas emissions and ecological degradation.

Health Risks: Research has raised concerns about the potential health impacts of Styrofoam, including the leaching of harmful chemicals into food and the environment.

Given these challenges, there is an urgent need for sustainable alternatives to Styrofoam, paving the way for innovations like mycelium packaging.

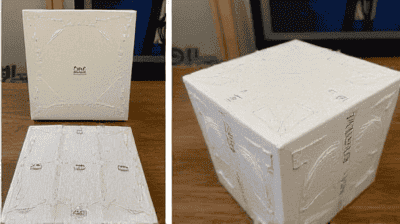

Mycelium packaging is created by cultivating mycelium on agricultural by-products such as straw, corn husks, and sawdust. The mycelium grows and binds these materials together, forming a dense, protective packaging material. Once fully grown, the mycelium is heat-treated to stop its growth, resulting in a sustainable and biodegradable product.

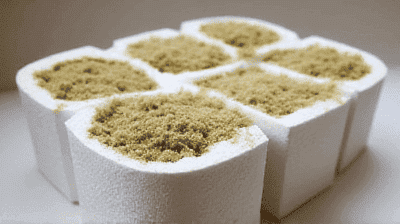

Material Selection: Agricultural by-products are chosen as the substrate for growing mycelium. These materials serve as food for the mycelium and provide structure for the final product.

Inoculation: The selected substrate is inoculated with mycelium spores, which begin to colonize the organic material. The mycelium uses the nutrients in the substrate to grow and expand.

Cultivation: The inoculated substrate is then placed in a controlled environment that provides the right temperature and humidity for mycelial growth. During this phase, the mycelium binds the substrate together, creating a solid mass.

Harvesting: Once the mycelium has fully colonized the substrate, the material is harvested. At this point, it has taken on a firm structure and is ready for further processing.

Heat Treatment: To stop the growth of mycelium and prevent decomposition, the material is heat-treated. This step ensures that the final product is stable and ready for use.

Finishing Touches: The mycelium packaging can be shaped and molded to meet specific packaging needs, making it versatile for various applications.

Biodegradability: Mycelium packaging is fully biodegradable, breaking down into organic material in a matter of weeks when exposed to natural conditions. This feature significantly reduces its impact on landfills and the environment.

Renewable Resource: The raw materials used in mycelium packaging come from agricultural waste, promoting a circular economy by utilizing surplus resources rather than relying on virgin materials.

Low Carbon Footprint: The production of mycelium packaging has a lower carbon footprint compared to Styrofoam. The cultivation process requires less energy and produces fewer greenhouse gas emissions, making it a more sustainable choice.

Safe for Human Health: Mycelium packaging does not leach harmful chemicals, making it a safer alternative for food packaging and other applications where human health is a concern.

Customizability: Mycelium packaging can be molded into various shapes and sizes, allowing brands to create customized packaging solutions that meet their specific needs.

Insulative Properties: Mycelium has excellent insulation properties, making it suitable for temperature-sensitive products such as food and electronics.

Mycelium packaging is finding a variety of applications across different industries:

Mycelium packaging is well-suited for food and beverage products. Its biodegradability and safety make it an ideal option for packaging fresh produce, take-out containers, and snacks. Brands seeking to enhance their sustainability profiles can use mycelium packaging as an alternative to plastic and Styrofoam.

In the electronics industry, mycelium packaging can provide protective casings for delicate items such as smartphones, laptops, and components. The insulative properties of mycelium protect products from damage during transportation while minimizing environmental impact.

As e-commerce continues to grow, there is a heightened demand for sustainable packaging solutions. Mycelium packaging can replace traditional packaging materials for shipping products, providing eco-friendly alternatives for brands committed to sustainability.

The cosmetics industry has also started adopting mycelium packaging for product containers and shipping materials. As consumers become more conscious of environmental impacts, brands are seeking biodegradable options to meet customer expectations.

Beyond packaging, mycelium has applications in the construction and design sectors. Researchers are exploring mycelium-based materials for insulation, wall panels, and even furniture. These innovative uses demonstrate the versatility of mycelium as a sustainable building material.

Several companies and organizations are leading the way in the development and use of mycelium packaging:

Ecovative Design, founded in 2007, is a pioneer in mycelium packaging. The company has developed a range of products, including packaging materials, insulation, and more. Their packaging has been adopted by various brands, including Dell, for shipping electronics.

Bolt Threads, a company known for its innovation in sustainable materials, has explored mycelium as a replacement for traditional packaging. They aim to integrate mycelium into their broader mission to create environmentally friendly alternatives for textiles and packaging.

The Mushroom Packaging Company focuses exclusively on developing mycelium-based packaging solutions. Their products are designed to minimize waste and promote sustainability while delivering effective protection for various goods.

IKEA has begun exploring mycelium packaging for its furniture products. As part of its commitment to sustainability, the furniture giant is actively seeking eco-friendly alternatives to conventional packaging materials.

In a bid to reduce plastic waste, Amazon has shown interest in using mycelium packaging for its delivery services. The company acknowledges the importance of sustainable packaging solutions and is investigating innovative materials to replace plastic.

While mycelium packaging presents numerous advantages, several challenges need to be addressed for widespread adoption:

Scaling up the production of mycelium packaging to meet industrial needs poses challenges. Establishing large-scale cultivation systems that maintain quality while ensuring efficiency can be complex.

Currently, the cost of mycelium packaging can be higher than that of traditional materials like Styrofoam. Achieving cost parity through improved production processes and economies of scale remains a hurdle.

Despite its potential, consumer awareness of mycelium packaging is still limited. Educating consumers about the benefits of mycelium packaging and its environmental impact is crucial for driving demand.

For mycelium packaging to become a mainstream solution, it must gain acceptance among brands and consumers. Convincing businesses to transition from established packaging methods to mycelium alternatives requires strategic marketing and education.

Establishing industry standards for mycelium packaging is essential to ensure consistency in quality and performance. As the market develops, collaboration among manufacturers, regulatory bodies, and industry stakeholders will be vital.

As consumers and industries increasingly seek sustainable solutions, the future of mycelium packaging appears promising. Here are some trends and developments to anticipate:

Continued research and development in mycelium cultivation and product design will lead to improved production methods and higher quality materials. Innovations in bioprocessing techniques will drive efficiency and scalability.

As more industries recognize the benefits of mycelium-based materials, the scope of applications will expand. New uses in construction, textiles, and beyond will leverage mycelium's unique properties.

Increased consumer awareness and demand for sustainable products will drive brands to adopt mycelium packaging. As consumers prioritize eco-friendly options, companies will respond with innovative packaging solutions.

Collaborations between businesses, researchers, and non-profit organizations will accelerate the development and adoption of mycelium packaging. Partnerships focused on sustainability will lead to knowledge sharing and best practices.

As sustainability becomes a priority for governments and regulatory bodies, support for materials like mycelium packaging may increase. Policies promoting biodegradable and renewable materials will encourage businesses to transition away from plastic packaging.

Mycelium packaging offers a groundbreaking solution to one of the most pressing environmental challenges of our time: plastic waste. By harnessing the natural properties of fungi, mycelium packaging provides a biodegradable, renewable, and safe alternative to traditional materials like Styrofoam. As technology advances and awareness grows, mycelium packaging has the potential to revolutionize the packaging industry, promote sustainable practices, and restore ecological balance.

With a commitment to innovation, collaboration, and sustainability, mycelium packaging is poised to play a vital role in a greener future. By choosing products packaged in mycelium, consumers can actively participate in reducing plastic waste and supporting a healthier planet for generations to come.